In the vast, humming world of industrial machinery, the pump is the unsung hero. It’s the heart of countless systems, from the municipal water lines beneath our feet to the complex chemical processing plants that power our economy. It works tirelessly, silently, and is completely ignored… until it fails. And when a critical pump fails, it’s never quiet. The results can range from a costly factory shutdown to a full-blown environmental crisis.

So, how do you prevent the preventable? You don’t just build a pump and hope for the best. You subject it to the ultimate final exam: End-of-Line (EoL) testing. This isn’t a simple spot check; it’s a rigorous, data-driven interrogation that confirms a pump is not just built, but built right. It’s the final, non-negotiable gatekeeper between the factory floor and the unforgiving real world.

Beyond the Blueprint: Where Theory Meets Reality

A pump’s design might look perfect on a CAD model. The simulations might run flawlessly. The spec sheet may promise a symphony of power and efficiency. But between the pristine digital blueprint and the cold, hard steel of the finished product, a thousand tiny variables can creep in. A microscopic flaw in a casting, a slight misalignment of an impeller, a seal that’s just a little too tight—these are the subtle gremlins that simulations miss but reality will brutally expose.

End-of-Line testing is the bridge over this chasm. It’s where theoretical performance is held accountable. It validates that the craftsmanship, the materials, and the assembly have all come together to create a product that doesn’t just meet the specs, but is truly fit for purpose.

The Staggering Cost of “Good Enough”

Skipping or skimping on robust EoL testing is one of the most expensive gambles a manufacturer can make. A single faulty pump that slips through the cracks can trigger a catastrophic domino effect:

- Warranty Nightmares: The cost of replacing a failed unit in the field—including labor, shipping, and a replacement—can obliterate the profit margin of dozens of successful sales.

- Operational Shutdowns: For your customer, a failed pump means immediate, costly downtime. And you can be sure whose name they’ll curse when their production line goes dark.

- Reputational Damage: Trust is fragile. A reputation for reliability takes years to build and only one high-profile failure to shatter.

In short, EoL testing isn’t a cost center; it’s one of the most effective forms of insurance a brand can have.

The Pump’s Gauntlet: What Are We Testing For?

Modern EoL testing is a sophisticated affair that measures a pump’s vital signs with incredible precision. Think of it as a comprehensive medical check-up before the pump is cleared for duty.

- Flow and Pressure: This is the pump’s core job description. Is it moving the right amount of fluid at the specified pressure? It’s the ultimate pass/fail on its fundamental purpose.

- Power Consumption: An inefficient pump is an energy vampire, silently draining a company’s resources over its entire lifespan. Testing ensures it performs as efficiently as designed.

- Vibration and Acoustics: A healthy pump has a smooth, consistent hum. Excessive vibration or noise is like a doctor hearing a heart murmur—it’s an early warning sign of internal problems that could lead to premature failure.

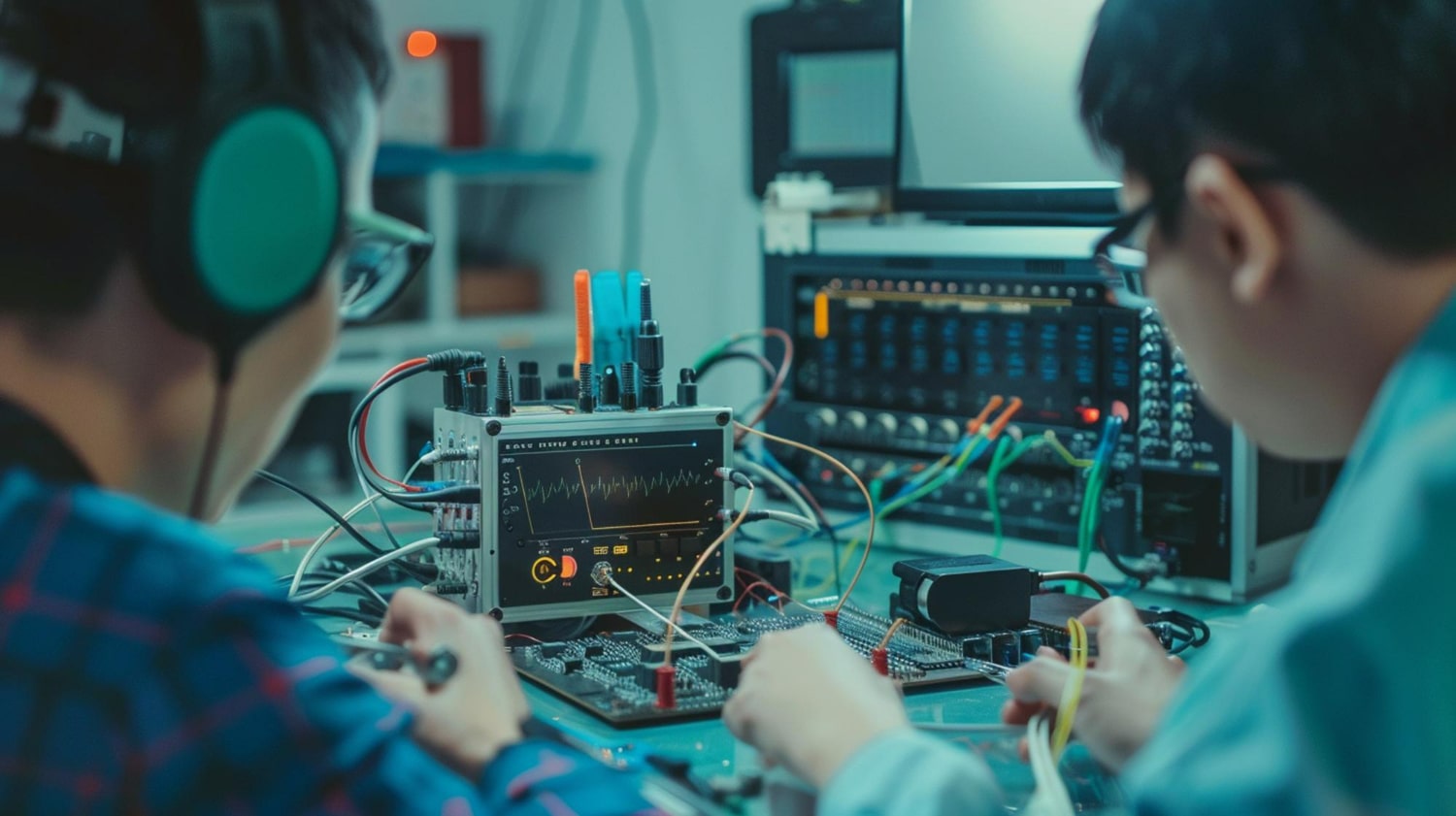

The Automation Advantage: Precision, Pace, and Proof

In the past, this testing was a manual, time-consuming process, prone to human error. Today, automated testers have revolutionized the game. These systems, like the Automated Pump Testers we design, are the gold standard for modern quality control.

An automated system doesn’t get tired. It doesn’t round numbers. It executes every test with relentless, robotic precision, time after time. It provides a rich, unambiguous dataset for every single unit that leaves the factory, offering indisputable proof of quality. This level of automation is a cornerstone of smart manufacturing solutions, replacing guesswork with certainty. And through our specialized design services, we can even create custom testing protocols for unique and complex pump designs.

Quality is a Verdict, Not a Goal

Ultimately, a commitment to rigorous End-of-Line testing is a declaration. It says that quality isn’t just a marketing buzzword, but the final verdict delivered on every product you ship. It’s the promise to your customer that the unseen, unsung hero you’ve sent them is ready for a long and productive life, ensuring that the day they have to think about it is a long, long time from now.