Automated PLC System Emulator

Revolutionizing Control System Testing with Hardware-in-the-Loop Simulation

Automated PLC System Emulator

In today’s fast-paced industrial landscape, the development and deployment of robust, reliable, and safe control systems are paramount. At the heart of most industrial automation processes lies the Programmable Logic Controller (PLC), a digital computer designed for the rigorous demands of manufacturing and process control. However, a critical and often overlooked challenge in the development lifecycle is the testing of the PLC program. Traditional methods are fraught with difficulties, requiring the presence of the entire operational hardware—a costly and often impractical necessity available only at the final stages of commissioning. This manual, time-consuming process is not only inefficient but also fails to generate reproducible results, leaving critical vulnerabilities in the system.

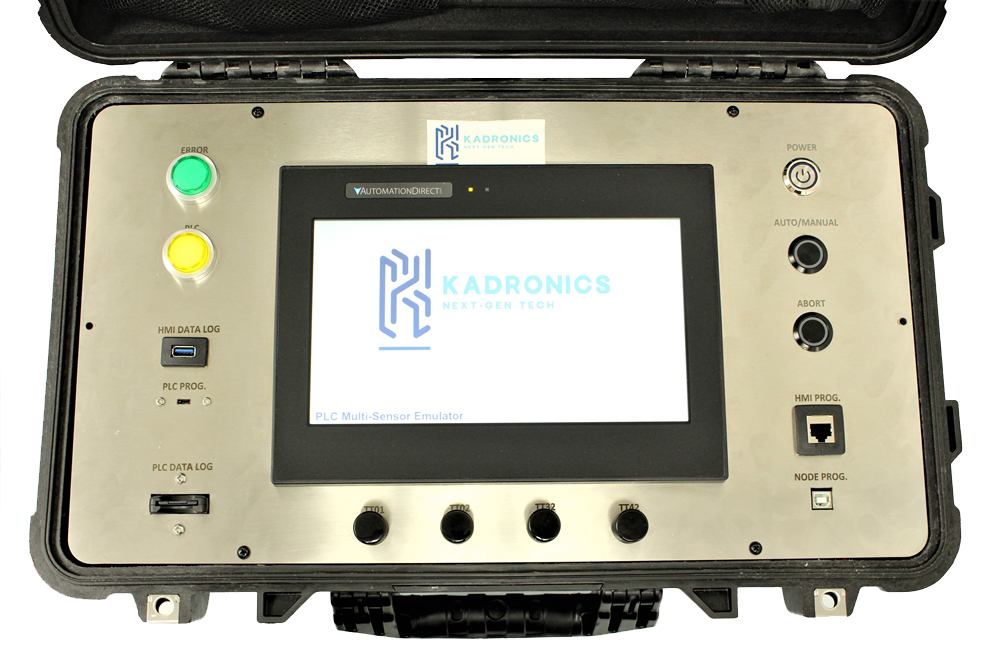

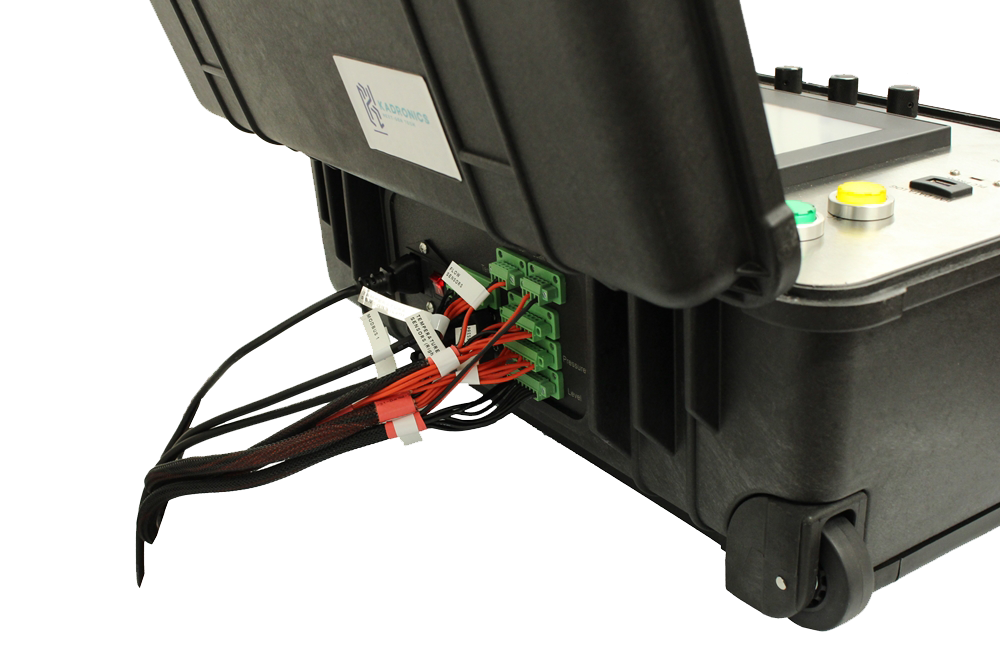

Recognizing this significant industry gap, Kadronics has developed a pioneering solution: the Automated PLC System Emulator. This portable, high-accuracy, and compact device is designed to fundamentally change how manufacturers test and validate their PLC programs. By emulating a wide array of field-level sensor inputs—such as pressure, humidity, temperature (PT1000), and ultrasonic level sensors—along with providing robust wiring continuity checks, the Kadronics emulator enables a paradigm shift from traditional, reactive testing to proactive, scalable, and reproducible simulation.

The core innovation of the Kadronics system lies in its ability to facilitate true Hardware-in-the-Loop (HIL) simulation. HIL testing is a sophisticated technique that allows for the verification of a controller’s design without the need for the complete physical system. Instead, a real-time model of the plant’s dynamic behavior is simulated, with the actual PLC connected and interacting with this model as if it were the real hardware. This powerful approach provides a controlled and safe environment to rigorously test control algorithms, identify potential flaws, and optimize performance long before the final hardware is assembled. The Kadronics emulator serves as the essential bridge in this process, providing the realistic sensor feedback that the PLC requires to execute its program.

The benefits of implementing the Automated PLC System Emulator are transformative for any manufacturing or automation firm. By enabling HIL simulation, Kadronics offers a solution that not only dramatically reduces the time and expense associated with testing but also significantly enhances the safety and quality of the final product. Imagine the ability to perform scalable and reproducible tests in a lab setting, even during the early development stages. This agile development process allows test engineers to tackle complex scenarios, including rare safety corner cases, without the risks inherent in testing on a live system.

The system’s ability to act as a digital twin of the whole system or specific parts of it provides an unparalleled level of flexibility. This means that new hardware components can be integrated and tested virtually upon availability, and crucial controller design changes can be made when they are still cost-effective to implement, eliminating the prohibitively high costs and delays of last-minute modifications.

The economic and operational advantages are clear. Traditionally, testing control algorithms has been a time-consuming, expensive, and potentially unsafe endeavor. The Kadronics Automated PLC System Emulator, by contrast, helps companies remain competitive and deliver high-quality controller software more efficiently. It replaces the cumbersome and risky traditional methods with a streamlined, modern approach. Test engineers are no longer tied to the physical constraints of the factory floor. They can now conduct comprehensive tests from the comfort and safety of their lab, accelerating the development cycle and bringing products to market faster. This leads to reduced commissioning times, fewer on-site issues, and a higher degree of confidence in the final system’s performance.

Furthermore, Automated PLC System Emulator professional and attractive design is a testament to its advanced capabilities. It is not merely a tool but a strategic asset. The compact form factor ensures portability, allowing the system to be used across different teams and locations. Its high-accuracy performance guarantees that the data fed to the PLC is reliable, ensuring that the test results are trustworthy and meaningful. This level of precision is critical for industries where even minor deviations can lead to significant operational failures. The emulator supports a variety of sensor types, making it a versatile solution for a wide range of applications, from industrial process control to mechatronics and robotics. It is an indispensable tool for engineers seeking to achieve excellence in their work, offering them the ability to simulate complex, multi-sensor environments with a single, intuitive device.

In conclusion, the Kadronics Automated PLC System Emulator is more than just a piece of hardware; it is a catalyst for innovation in the industrial automation sector. By providing a safe, accurate, and cost-effective platform for Hardware-in-the-Loop simulation, it empowers engineers to move beyond the limitations of traditional testing. It enables agile development, promotes early identification of design flaws, and ensures that controller software is robust and reliable before it ever goes live. For companies committed to delivering excellence and staying ahead of the curve, the Kadronics emulator represents a vital investment in their future, transforming the challenges of PLC testing into a strategic advantage that drives efficiency, quality, and safety across the entire product lifecycle. Automated PLC System Emulator by KADRONICS!

In today’s competitive landscape, the Automated PLC System Emulator isn’t just a tool; it’s a strategic investment in a company’s future. It facilitates a move away from reactive problem-solving—where issues are discovered late in the development cycle—to a proactive, preventative approach. This shift dramatically reduces the risk of costly recalls, unplanned downtime, and reputational damage. By enabling comprehensive Hardware-in-the-Loop (HIL) simulation, the Kadronics emulator allows engineers to conduct stress tests and validate safety-critical functions under conditions that would be too dangerous or impractical to replicate on physical hardware. This includes simulating fault conditions, system overloads, and sensor failures to see how the PLC responds. The detailed and reproducible data generated from these tests provides invaluable insights, allowing for continuous improvement of the control algorithms and overall system design. Ultimately, this leads to a final product that is not only highly functional and efficient but also inherently safer and more reliable, giving companies a significant competitive edge in the global market. The ability to innovate and iterate faster, with greater confidence, is the ultimate outcome of adopting this advanced emulation technology.

Testing PLC programs is difficult, requiring the presence of full operational hardware at the final stage of commissioning, which is costly and inefficient. This outdated process creates critical project risks, as late-stage errors lead to significant delays and budget overruns, and testing safety-critical functions becomes dangerous. The Kadronics Automated PLC System Emulator solves this by enabling a professional Hardware-in-the-Loop (HIL) simulation environment, allowing you to test control logic and sensor inputs with high accuracy from the initial development phase, ensuring a reliable, safe product and a faster time-to-market.